Renovation of Stora Enso Imavere Log Sorting Yard 9 years later

In July 2016, a project was carried out to renovate the deteriorated log sorting yard at Stora Enso’s Imavere facility. The yard, originally constructed during the Soviet era, had been in constant use for decades. Over time, the subsoil had subsided, the pavement had significantly degraded, and several soft, waterlogged areas had formed—areas where repeated filling and maintenance had proven ineffective. The primary goal of the renovation project was to stabilize and improve the structural integrity of the yard’s surface and subbase to ensure its durability and long-term usability.

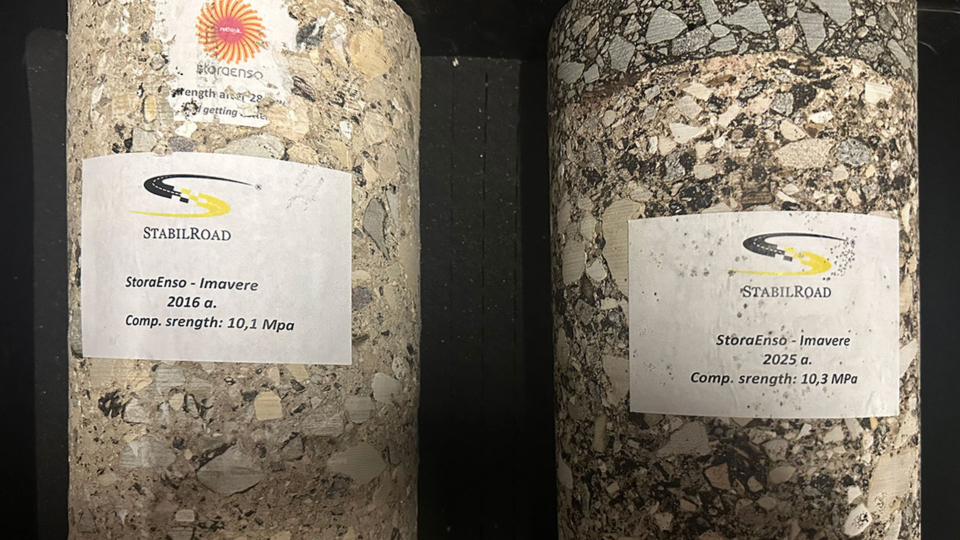

To achieve this, the StabilRoad technology was employed. Remarkably, stabilization work covering nearly 4,000 square meters was completed in just one day, using only the existing onsite materials for recycling. Six months later—following inspection and approval by the Finnish owners—a 4 cm asphalt layer was applied over the stabilized surface. Since the renovation, the yard has been subject to daily heavy-duty use, including continuous loading and operation by 40-ton log forklifts. Over the course of nine years, there have been no signs of wear or structural degradation. On the contrary, recent soil sample analyses indicate an increase in compressive strength, demonstrating the long-term effectiveness of the stabilization method.